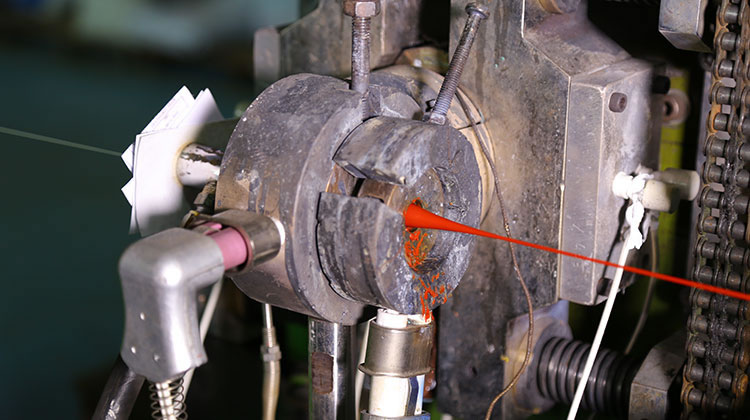

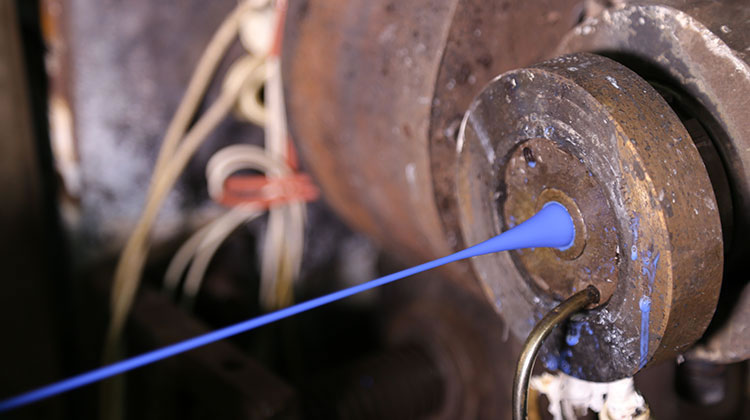

Extrusion workshop:

High-quality wires and cables are manufactured in the extrusion workshop, which is equipped with advanced equipment and an automatic control system.

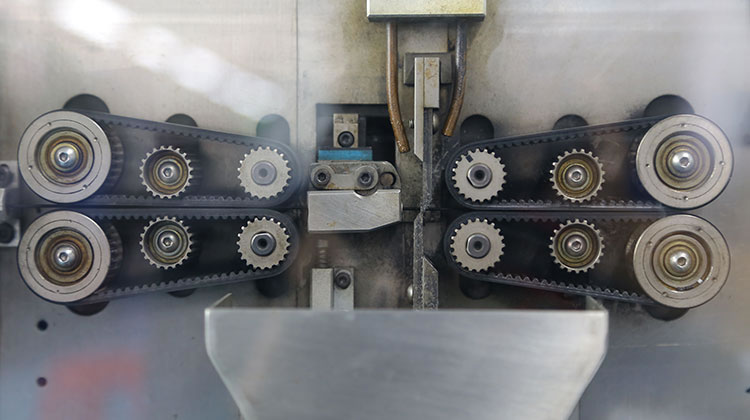

Weaving workshop:

Automated high-speed weaving machines produce wire rods of high shielding rate catering to diverse requirements. Coaxial lines are available here to provide shielding service.

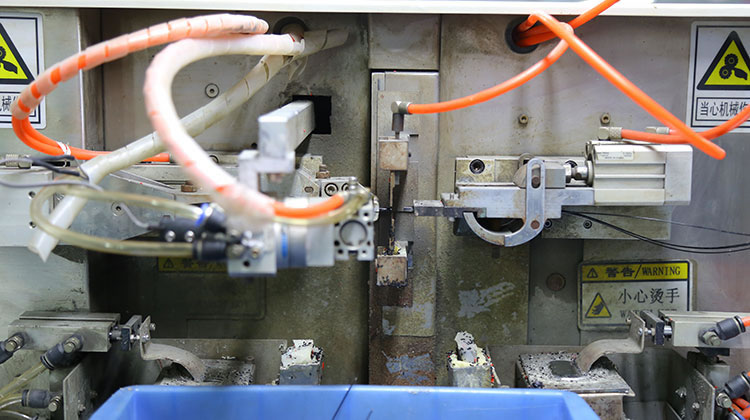

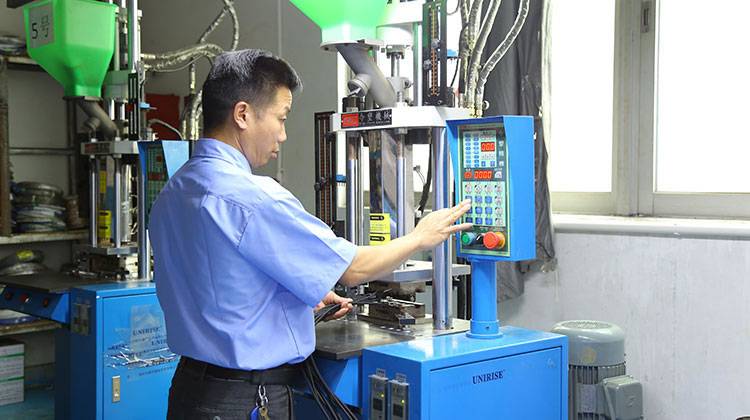

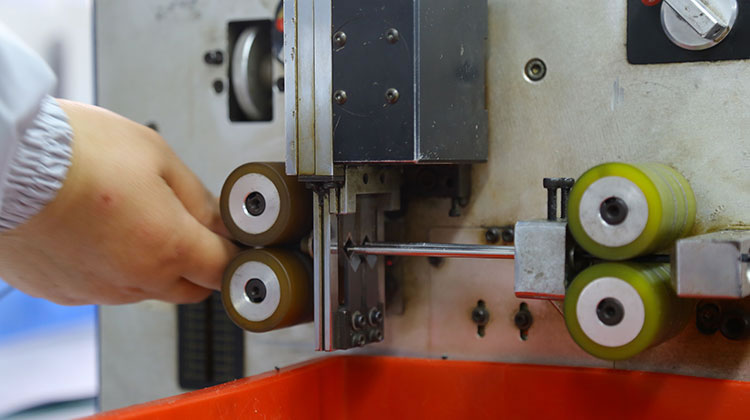

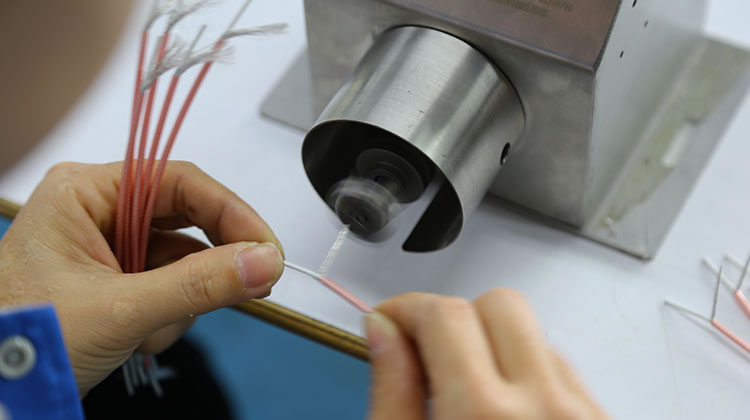

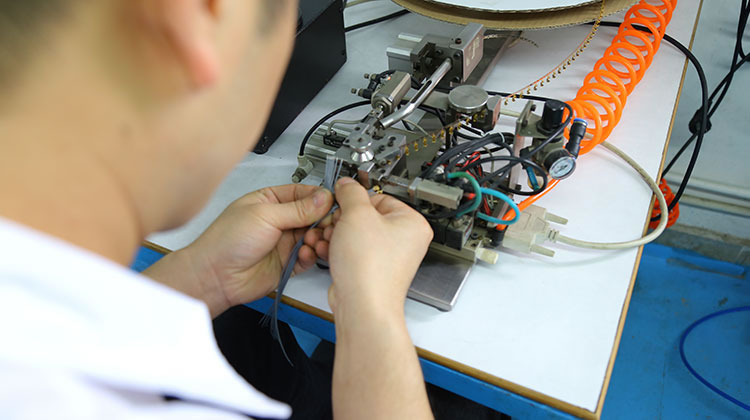

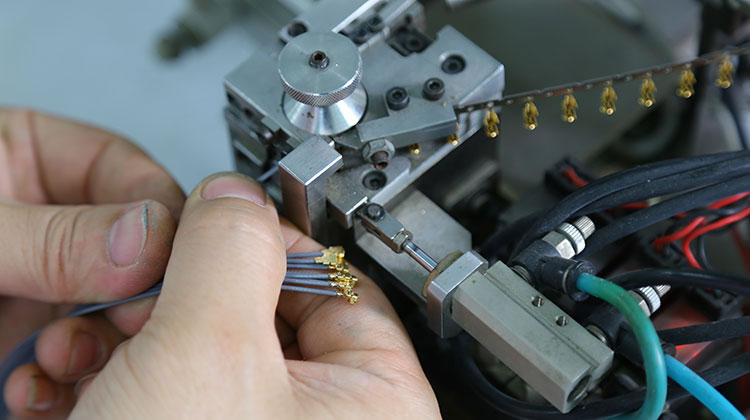

Processing workshop:

The workshop is used to provide supporting services, such as wire stripping, crimping, tinning, and so on.

Warehouse:

We have a systematic management process for products entering the warehouse and their storage. This system allows for an orderly management for the input-output of products and raw materials.

We have four extrusion lines, completely meeting the production needs of the market.

Extrusion line

Extrusion line

Insulation layer

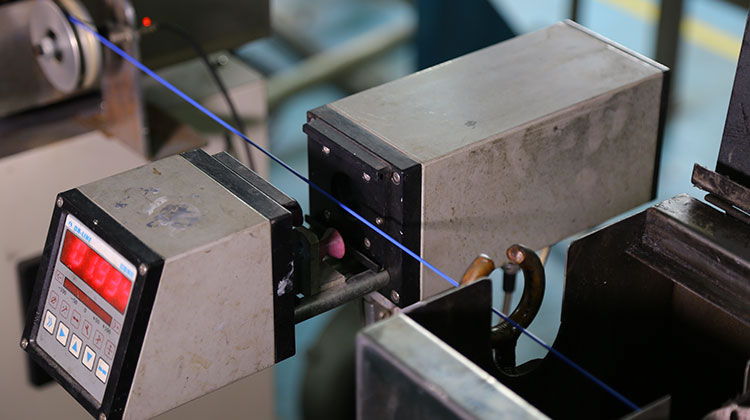

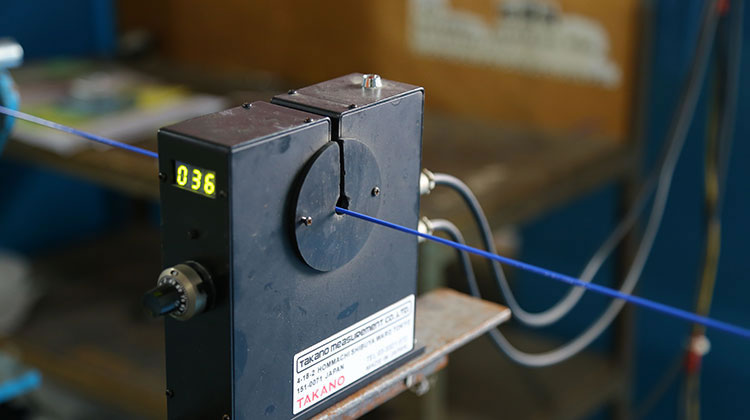

Measuring the diameter of wire

Measuring the diameter of wire Wire surface treatment before printing

Wire surface treatment before printing Drying with high temperature

Drying with high temperature Printing

Printing Cooling process

Cooling process High voltage detection

High voltage detection Diameter detection before receiving wire

Diameter detection before receiving wire Storage area

Storage area Storage area

Storage area Checking the diameter of finished products

Checking the diameter of finished products

We possess 20 weaving machines, completely meeting the needs of market. Automated high-speed weaving machines can produce wires with high shielding rate which can cater to diverse requirements. And coaxial wires are produced here.

Stranding machine

Wire processing workshop

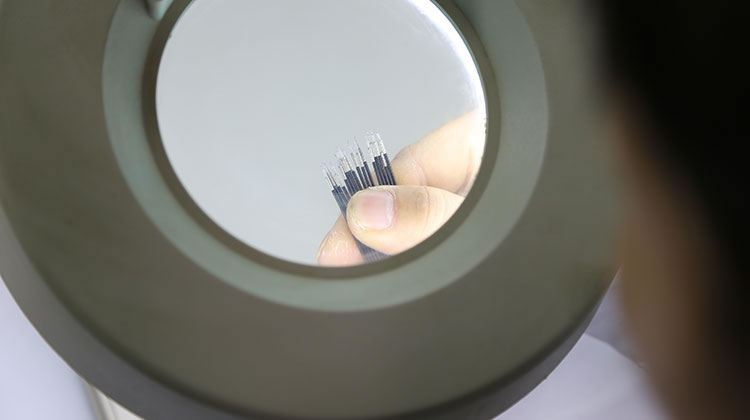

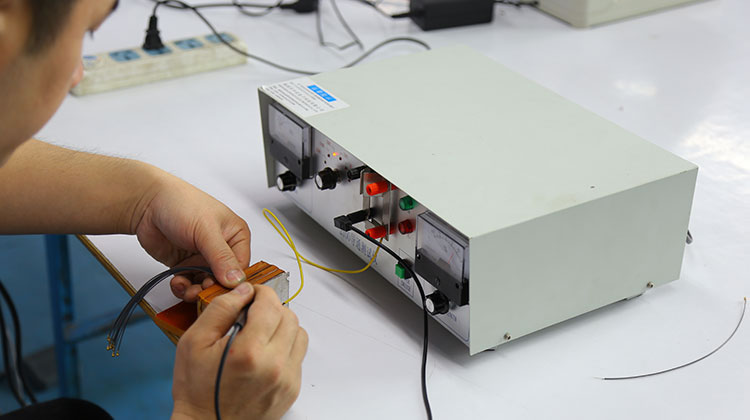

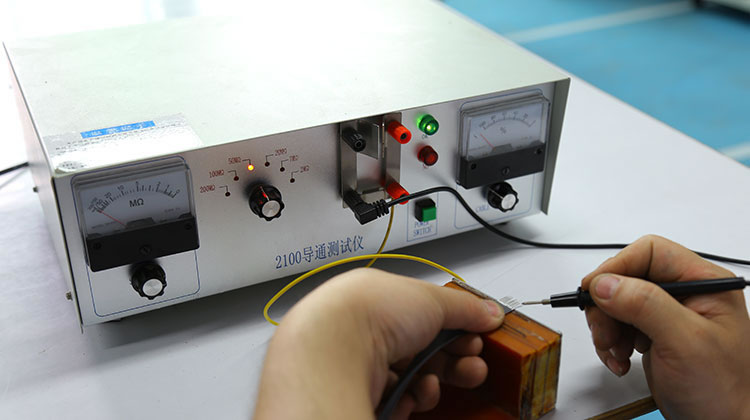

Wire processing workshop Detection

Detection

The workshop director checks the wire products.

Automatic wire cutting machine

Automatic injection molding machine

Wire cutting machine

Tinning

Automatic cutting machine

Wire twisting machine

Online detection

Terminal crimping machine

Connectivity test

Wire stripping machine

Stranding machine

Packaging product

Dongguan Qinda Wire Co., Ltd.

Add.: No.9 Yingui Road, Sangyuan Industrial Area, Dongcheng District, Dongguan City, Guangdong Province, China

Tel.: +86-4000518165 (Six Lines)

Fax: +86-769-21980193

Contact:

Rainbow sales@qindawire.com

Ge Hu huzong@qindawire.com

Nicole waimaobu@qindawire.com